ChipCheck

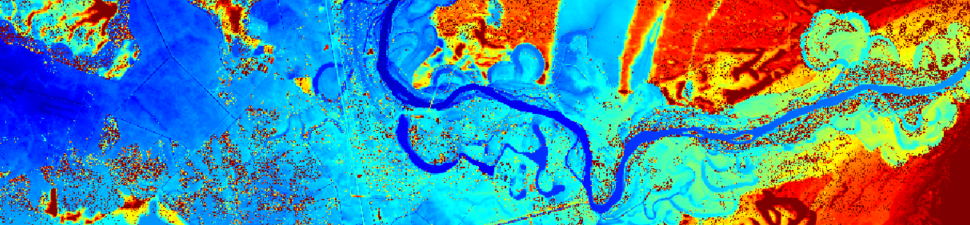

Development of Novel X-ray Inspection System for Fast Automated Detection of Counterfeit PCB Components

Currently, electronics manufacturers do not check all PCB components at goods inwards. Some manufacturers make random checks on single components from batches of component lots. ChipCheck project is for the development of a novel X-ray inspection system for fast automated detection of counterfeit PCB components.

Project duration: 24 months (2010-2012)

Partners: TWI (UK- coordinator), Innospexion APS (Denmark), Accent Pro 2000 s.r.l (Romania), Computerised Information Technology Ltd (UK), Semicon Sp. z o. o.(Poland), Kentro Erevnas Technologias Kai Anaptyxis Thessalias (Greece), Surface mount and related technologies Ltd (UK), Institute of Electronics and Computer Science (Latvia)

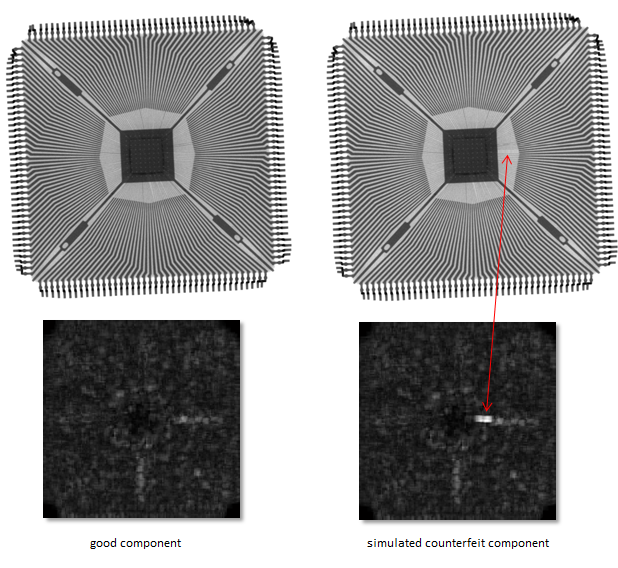

IECS developed counterfeit component detection software package COFDET featuring:

- Automatic object position compensation

- Detection of changes in image fragments

- Automatic component sentencing after training from known good components

- Analysis of images in real time mode (less than 0.5s)

- Compiled MATLAB code with MEX functions

COFDET is distributed by the ChipCheck consortium within the X-ray system for testing electronic components at goods-inwards.

Web: CHIPCHECK